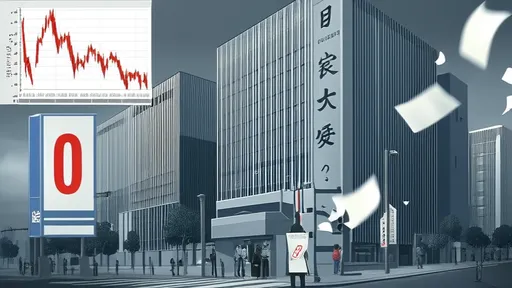

The World Trade Organization has issued a stark warning about the growing costs of trade fragmentation, estimating that a breakdown in global cooperation could slash worldwide GDP by up to 7%. This sobering projection comes as geopolitical tensions and pandemic-era supply chain disruptions continue reshaping international commerce patterns.

'Trade fragmentation isn't painless', WTO Director-General Ngozi Okonjo-Iweala emphasized during the organization's recent annual report presentation. "What we're seeing isn't just routine decoupling but potentially costly duplication as countries pursue parallel supply chains." The report suggests that while some nations might gain short-term advantages from reshoring production, the broader economic toll could exceed $5 trillion in lost output.

The WTO analysis identifies several pressure points accelerating trade fragmentation. The US-China tech war has spawned competing semiconductor ecosystems, while the Ukraine conflict has reconfigured energy and agricultural flows. Meanwhile, the pandemic's legacy includes both genuine supply chain diversification and what some economists call "redundancy for redundancy's sake" - duplicate factories and inventory buffers that may prove economically inefficient.

Developing nations face particularly acute dilemmas. Countries like Vietnam and Mexico have benefited from "friendshoring" as Western companies seek alternatives to Chinese manufacturing. However, WTO data shows these gains remain concentrated in specific sectors, with many smaller economies struggling to attract meaningful investment. "The reality is that most supply chain relocation stays within regional blocs," noted one Geneva-based trade diplomat. "It's less about 'China vs Vietnam' and more about 'North America reshoring to Mexico' or 'Europe moving production to Eastern Europe.'"

The automotive industry exemplifies this complex reshuffling. European carmakers have accelerated battery plant construction within the EU to qualify for green subsidies, while US automakers leverage Inflation Reduction Act incentives to rebuild domestic supply chains. Asian manufacturers, meanwhile, are doubling down on regional free trade agreements. "We're not deglobalizing so much as re-globalizing into competing spheres," observed a senior auto executive who requested anonymity due to the sensitivity of ongoing relocation decisions.

Technology sectors reveal even starker divides. The US CHIPS Act has spurred over $200 billion in domestic semiconductor investments, while China pours similar sums into achieving self-sufficiency. This bifurcation forces suppliers like ASML or TSMC to maintain parallel technology tracks - an expensive proposition that ultimately raises costs for end users. "The golden era of hyper-efficient global supply chains may be ending," lamented a Taiwanese tech executive. "We're entering an age where national security trumps pure economics."

Food security concerns have also driven fragmentation. After Russia's invasion of Ukraine triggered grain shortages, Middle Eastern and African nations scrambled to diversify agricultural imports. India initially filled some gaps but then restricted rice exports, demonstrating how quickly crisis responses can morph into protectionism. "Every country now wants to control its own food destiny," said an African trade official, "even if that means paying more for less reliable local production."

The services sector isn't immune either. Digital nationalism has led to data localization laws from Brussels to Bangalore, forcing cloud providers to build redundant infrastructure. Professional services firms report clients increasingly prefer "politically aligned" consultants for sensitive projects. Even academic research faces new barriers, with cross-border collaboration declining in strategic fields like AI and quantum computing.

Amid these shifts, certain unexpected beneficiaries emerge. Logistics hubs like Dubai and Singapore are thriving as middlemen in reconfigured trade routes. Shipping firms have adapted to longer voyages as companies avoid conflict zones. Manufacturers of industrial automation equipment report surging demand as companies reshore production to high-wage countries. "Robots don't care about labor costs," quipped a German robotics CEO, "which makes them perfect for this new era of expensive redundancy."

Developing nations with stable governance and trade agreements are attracting manufacturing investments previously destined for China. Vietnam's exports to the US have doubled since 2018, while Mexico surpassed China as America's top trading partner this year. However, infrastructure bottlenecks and skills gaps limit how much these countries can absorb. "There simply aren't enough qualified workers or ports to handle complete supply chain relocation," explained a Vietnamese economics professor.

The WTO warns that without guardrails, fragmentation could trigger a vicious cycle. As trade barriers rise, economic growth slows, fueling political pressures for more protectionism. Their modeling suggests that in a full-blown decoupling scenario, some developing nations could see GDP losses exceeding 10% - devastating figures for economies already struggling with debt burdens. "We're not arguing against prudent diversification," clarified one WTO economist, "but against knee-jerk duplication that ignores comparative advantage."

Some multinationals are pursuing hybrid strategies. Rather than complete reshoring, they're building "China plus one" supply chains while maintaining certain Chinese production for that market. Others are stockpiling inventory - the "just in case" replacement for lean "just in time" systems. These adaptations come with costs; global corporations report supply chain expenses have risen 15-20% since 2020, eating into profit margins.

The geopolitical dimension complicates matters further. Western policymakers increasingly frame trade choices as democracy-versus-autocracy decisions, while developing nations resist being forced to choose sides. "We don't want our economic development held hostage to great power competition," asserted an Indonesian trade official during recent WTO consultations. This sentiment echoes across Global South capitals wary of becoming collateral damage in US-China tensions.

Looking ahead, the WTO urges renewed focus on multilateral frameworks to manage competition without complete disintegration. Potential measures include modernizing dispute resolution systems, creating safeguards for essential goods trade, and establishing clearer rules for national security exceptions. "The alternative," warns Okonjo-Iweala, "is a poorer, less stable world where trade becomes another arena for zero-sum conflict rather than shared prosperity."

As supply chains continue evolving, one reality becomes clear: there are no true winners in fragmentation, only relative losers. The companies and countries that adapt most successfully will likely be those finding ways to maintain international connections while navigating new geopolitical realities - a delicate balancing act with trillions of dollars at stake.

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 23, 2025

By /Jun 3, 2025

By /Jun 3, 2025